support@kanede.com

support@kanede.com Search

Search

0

0Double acting scotch yoke pneumatic actuator Specification:

Comply to UNI EN 15714-3:2009 standard

ISO connection standard:UNI EN ISO 5211。

Auxiliary connectioin:NAMUR,VDI/VDE3845

Control angle:90°(-5°~+3°)。

Torque:Relative to control pressure and type.

Working Condition:

Operation temperature:-20℃~+80℃

Pressure:2-8bar

Operating Medium:Filtered compressed air dry or lubricated.The pressure condensation point in accordance with

(ISO 8573-1:2010, Class 3)has to be ≤ - 20℃ or 10℃under ambient temperature.

The maximum particle size in accordance with (ISO 8573-1:2010, Class 5) should not exceed 40 µm.

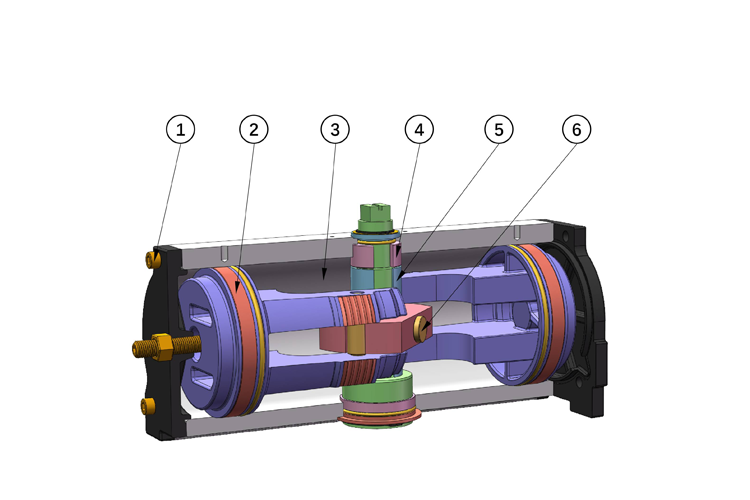

Single/Double acting scotch yoke pneumatic actuator butterfly valve Features:

1.Corrosion-resistant connectors All connection bolts are stainless steel with good corrosion resistance 2.Piston ring The piston guide ring, made of ultra high molecular polymer, has an extremely low coefficient of friction, while the material has high hardness and excellent wear resistance, providing precise guidance and long service life. 3.Body The cylinder body is processed with high precision and anodized. The thickness of the oxide layer is more than 20μm. It has low friction coefficient and excellent anti-corrosion and wear resistance. 4.Shaft bearing Prevent direct contact between shaft and cylinder block, ensure the positioning accuracy of drive shaft, reduce friction loss, prevent direct contact between shaft and cylinder block, make the actuator efficient operation. 5.Piston bearing Ensure the positioning accuracy of the piston, so that the piston can be smooth and smooth operation, prevent shifting. 6. Pin connection The fork and the drive shaft are connected by pins to ensure that the fork and the drive shaft run synchronously. At the same time, the pins also play a role in preventing the drive shaft from flying out, which is a reliable and safe design. |

Torque table (Nm):

| Model Pressure | 2.5bar/36psi | 3bar/44psi | 4bar/58psi | 5bar/73psi | 5.5bar/80psi | 6bar/87psi | 7bar/101psi | 8bar/116psi | ||||||||||||||||

| α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | α=0° | α=45° | α=90° | |

| DA40 | 13 | 6 | 10 | 15 | 8 | 12 | 20 | 10 | 16 | 25 | 13 | 20 | 28 | 14 | 22 | 30 | 15 | 24 | 35 | 18 | 28 | 40 | 20 | 32 |

| DA60 | 37 | 19 | 30 | 44 | 23 | 36 | 59 | 30 | 48 | 74 | 38 | 60 | 83 | 42 | 68 | 89 | 45 | 72 | 104 | 53 | 84 | 118 | 60 | 96 |

| DA70 | 71 | 36 | 58 | 86 | 44 | 70 | 114 | 58 | 93 | 143 | 73 | 116 | 160 | 81 | 130 | 171 | 87 | 140 | 200 | 102 | 163 | 228 | 116 | 186 |

| DA80 | 115 | 59 | 94 | 138 | 70 | 113 | 184 | 94 | 150 | 230 | 117 | 188 | 258 | 131 | 210 | 276 | 141 | 225 | 322 | 164 | 263 | 368 | 188 | 300 |

| DA90 | 172 | 87 | 140 | 206 | 105 | 168 | 274 | 140 | 224 | 343 | 175 | 280 | 384 | 196 | 313 | 412 | 210 | 336 | 480 | 245 | 392 | 549 | 280 | 448 |

| DA100 | 252 | 129 | 206 | 303 | 154 | 247 | 404 | 206 | 329 | 505 | 257 | 411 | 565 | 288 | 461 | 605 | 309 | 494 | 706 | 360 | 576 | 807 | 411 | 658 |

| DA125 | 412 | 210 | 336 | 494 | 252 | 403 | 659 | 336 | 537 | 823 | 420 | 671 | 922 | 470 | 752 | 988 | 504 | 806 | 1153 | 588 | 940 | 1317 | 672 | 1074 |

| DA140 | 575 | 293 | 469 | 690 | 352 | 563 | 920 | 469 | 750 | 1150 | 586 | 938 | 1288 | 657 | 1050 | 1380 | 704 | 1125 | 1610 | 821 | 1313 | 1840 | 938 | 1501 |

| DA160 | 870 | 443 | 709 | 1044 | 532 | 851 | 1392 | 709 | 1135 | 1740 | 887 | 1418 | 1948 | 993 | 1589 | 2088 | 1064 | 1702 | 2435 | 1241 | 1986 | 2783 | 1419 | 2269 |

| DA180 | 1213 | 618 | 989 | 1456 | 742 | 1187 | 1941 | 989 | 1583 | 2426 | 1237 | 1978 | 2718 | 1385 | 2216 | 2912 | 1484 | 2374 | 3397 | 1731 | 2770 | 3882 | 1979 | 3165 |

| DA220 | 2071 | 1082 | 1565 | 2485 | 1299 | 1878 | 3314 | 1732 | 2504 | 4142 | 2165 | 3130 | 4639 | 2425 | 3506 | 4971 | 2598 | 3756 | 5799 | 3031 | 4382 | 6627 | 3464 | 5008 |

| DA260 | 4256 | 2224 | 3216 | 5107 | 2669 | 3859 | 6810 | 3559 | 5146 | 8512 | 4449 | 6432 | 9534 | 4983 | 7204 | 10215 | 5339 | 7719 | 11917 | 6228 | 9005 | 13619 | 7118 | 10292 |

E-mail: support@kanede.com

Tel: 0086-519-85557268

Fax: 0086-519-85557368

Add: No. 206 Yuntaishan Road., Xinbei District, Changzhou, Jiangsu province, China